Description

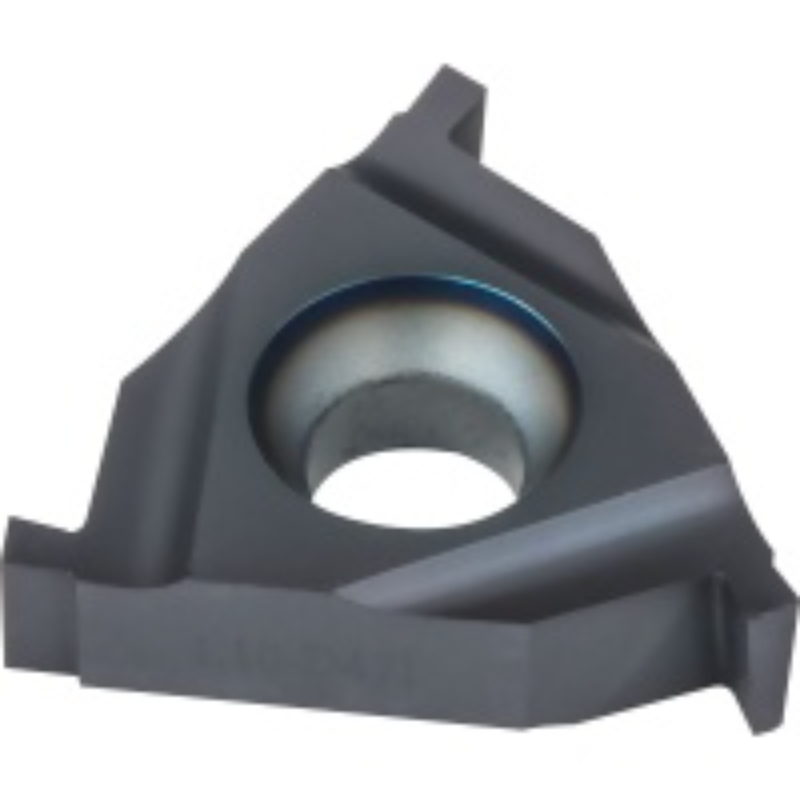

Used for shallow grooving, precision ground with sharp edge.

These inserts are used in standard external threading tools for 16ER inserts.

Grade T350 is NANO-TiAlSiN coated with a substrate of high wear resistance micro-grain carbide and is our preimium grade for all types of steel and stainless also good for cast iron and other materials first choice for general use.

This PVD coated grade covers P25, M25, K30, S15, H10 range of materials, suitable for dry cutting.

Suitable for a standard 16mm threading tool holder.

| Material | Hardness HB | Cutting Speed VC: m/min | Feed mm/rev | Application Choice |

| Non alloyed steel 0-0.45% C | 125-170 | 70-100 | 0.03-0.05 | Good |

| Low alloyed steel | 180-350 | 50-90 | 0.03-0.05 | Good |

| High alloyed steel | 200-325 | 40-65 | 0.03-0.05 | Good |

| Corrosion resistant steel | 200 | 55-80 | 0.03-0.05 | Good |

| Stainless – Ferritic | 200-330 | 35-90 | 0.03-0.05 | Good |

| Stainless – Austenitic | 180-200 | 30-80 | 0.03-0.05 | Good |

| Stainless – Cast Ferritic | 200-330 | 30-80 | 0.03-0.05 | Good |

| Stainless – Cast Austenitic | 200-330 | 30-70 | 0.03-0.05 | Good |

| Grey cast iron | 180-260 | 50-60 | 0.03-0.05 | OK |

| Spheroidal cast iron | 160-260 | 60-100 | 0.03-0.05 | OK |

| Malleable / Tempered iron | 130-230 | 50-80 | 0.03-0.05 | OK |

| Aluminium Wrought Alloys | 60-100 | 200-500 | 0.03-0.05 | OK |

| Aluminium Castings Si<12% | 80-90 | 100-300 | 0.03-0.05 | OK |

| Aluminium Alloys Si 12%-23% | 130 | 100-200 | 0.03-0.05 | OK |

| Bronze & Brass | 90-100 | 80-150 | 0.03-0.05 | OK |

| Iron Based Hi-temp Alloys 200-280 HB | 200-280 | 20-25 | 0.03-0.04 | Good |

| Nickel or Cobalt Based 250 HB | 250 | 15-20 | 0.03-0.04 | Good |

| Nickel or Cobalt Based 30-58 HRC | 350 | 15-20 | 0.03-0.04 | Good |

| Pure Titanium | 400Rm | 40-60 | 0.03-0.05 | Good |

| Titanium Alpha + Beta Alloys | 1050Rm | 15-30 | 0.03-0.05 | Good |

EMC

EMC

Reviews

There are no reviews yet.