Description

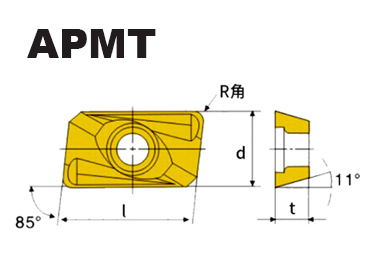

APMT 1604 PDER Carbide Inserts (Box 10):

To fit BAP 400R Milling Tool Holders

Quick Detail:

- Good thermal hardness

- Excellent wear resistance

- Improve production efficiency

- With PVD and CVD coating

- Al2O3 and TiN coatings

Description:

- APMT tungsten carbide inserts are made of 0.6UM micro tungsten steel, which has high wear resistance and strength and belongs to high hardness. High speed cutting special turning tool; The cutting edge is sharp, the cutting strength is high, and the chip breaking groove edge bandwidth can reduce the cutting pressure and improve the service life of the cemented carbide blade.

Specifications:

|

Modle

|

l(mm)

|

d(mm)

|

t(mm)

|

|

APMT1135

|

11

|

6.35

|

3.5

|

|

APMT1604

|

16.5

|

9.525

|

4.76

|

|

APMT1605

|

16.5

|

9.525

|

5.1

|

|

APKT1003

|

6.67

|

3.55

|

2.8

|

|

APKT160408

|

17.5

|

9.525

|

5.77

|

Notice:

- The tungsten carbide inserts shall not be collided or dropped on the ground and must be handled with care.

- Before installing the tungsten carbide inserts, the performance and purpose of the saw table must be confirmed to ensure that the cutting direction indicated by the blade arrow is consistent with the rotation direction of the saw table. It is strictly prohibited to install in the opposite direction. Wrong installation direction may cause the blade sawtooth to fall off, so as to prevent accidents.

- After installation, it is necessary to confirm whether the central hole of the carbide blade is firmly fixed on the flange plate of the saw table. If there is a gasket, the gasket must be sleeved; Then, gently push with your hand to confirm whether the blade rotates eccentrically.

- When using, do not exceed the specified high speed

- When the tungsten carbide inserts is not used, hang the blade vertically on the dry shelf.

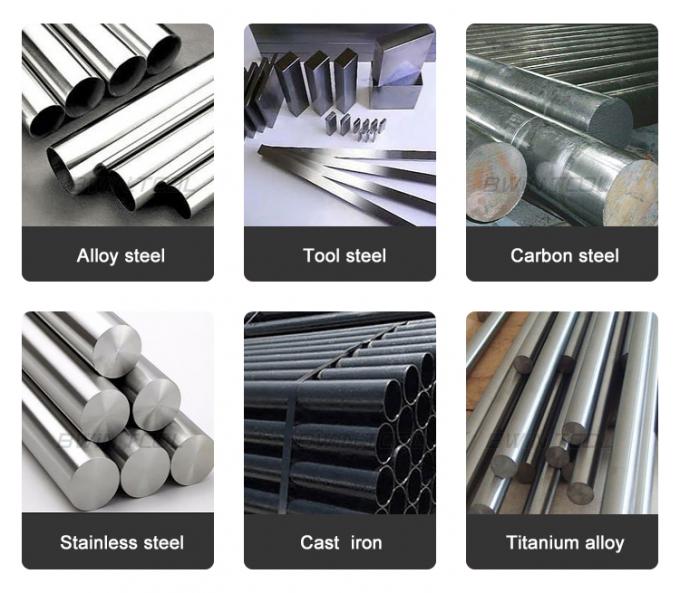

Applications:

Our tungsten carbide inserts could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

AG60 -11

AG60 -11

Reviews

There are no reviews yet.