Description

Walton Tap Extractors let you remove broken machine screw and hand taps, pipe taps and STI taps without drilling, lasers, damaged threads, scrapped parts or repair inserts.The hardened steel fingers of these extraction tools fit in the flutes of a broken tap to back it out simply and safely. This effective method has been used since 1908. Tap Extractors are available in every tap size – both inch and metric – as handy sets or individual pieces. They will fit both NC and NF taps.

Walton Tap Extractors are designed specifically for:

- #4 to 1-1/2” machine screw and hand taps

- 3mm to 38mm taps, in all standard flute sizes

- 1/8” to 1” pipe taps

- #4 to 5/8” helical coil “STI” taps

How to Remove a Broken Tap with Walton Tap Extractors

Since 1908, performance professionals have depended on our tap extractors as their first, best option for quickly getting out broken taps. Whether from an engine block, manifold, or an important part (aluminum, steel — you name it), in three simple steps you may be able to remove a broken tap without drilling, lasers, damaged threads, scrapped parts, or repair inserts.

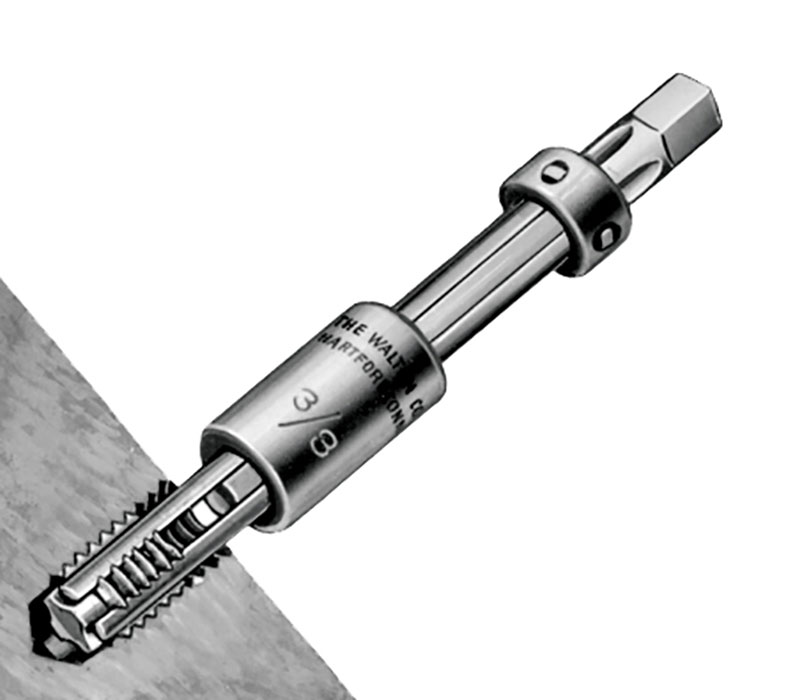

Step 1

Thoroughly remove all chips of the broken tap. Insert the Extractor fingers into the flutes of the broken tap, pushing them gently, but firmly, into position.

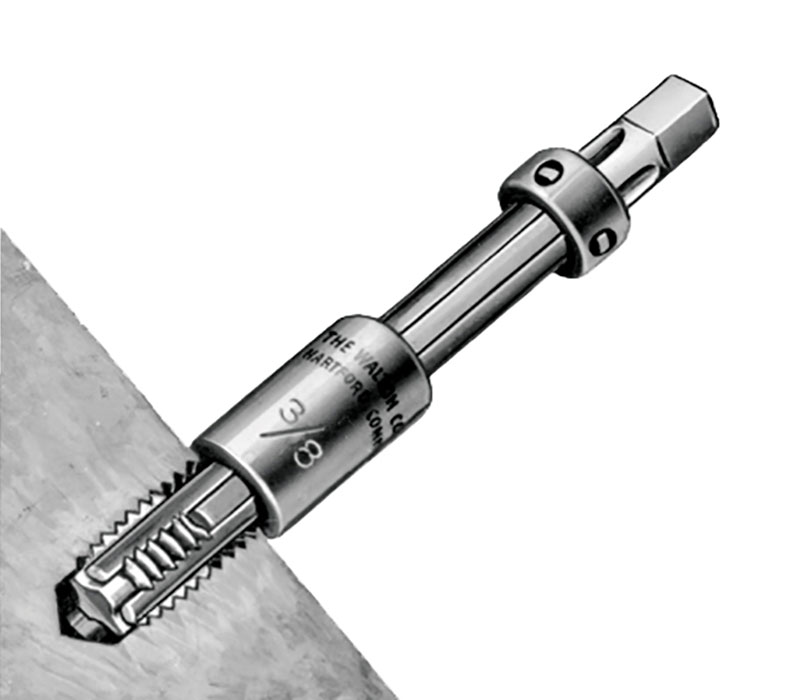

Step 2

Push the holder down until it touches the broken tap. Slide the sleeve down until it touches the work.

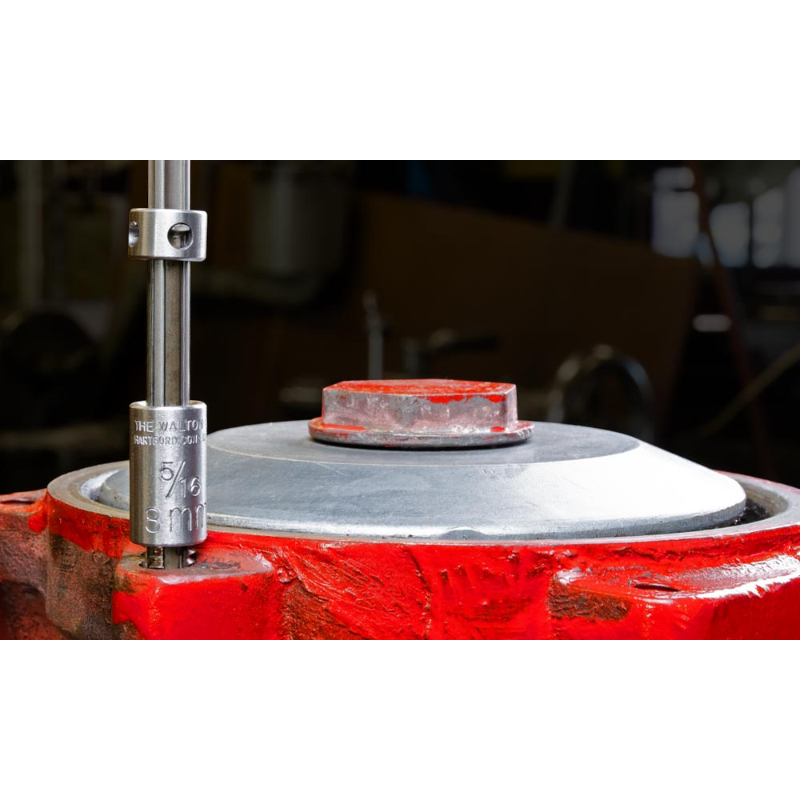

Step 3

Apply a tap wrench to the square end of the holder. Twist forward and backward a few times to loosen, then back out the broken tap.

Getting a Broken Tap Out of an Exhaust Manifold

Reviews

There are no reviews yet.